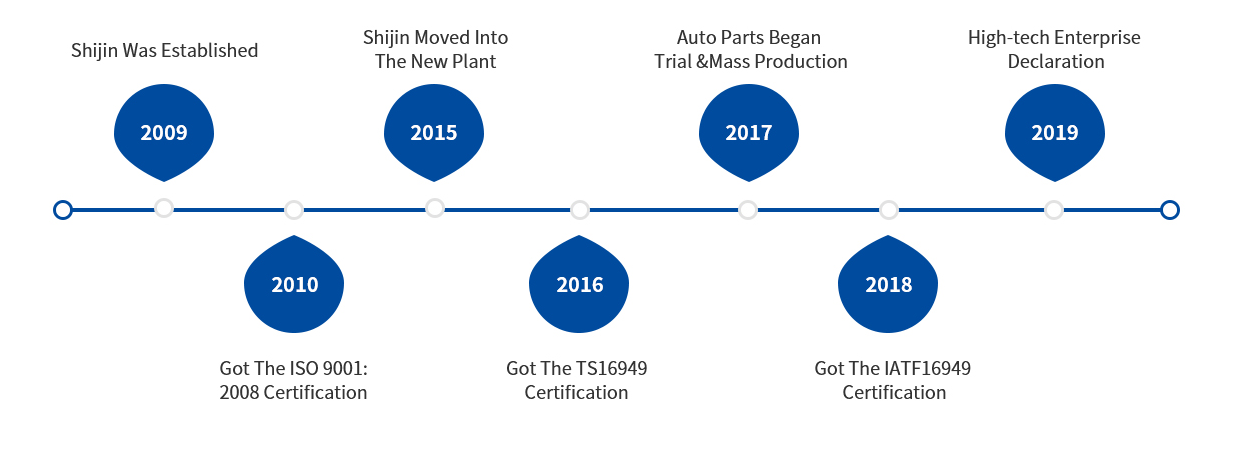

Shijin was established in June 2009, is a manufacturing company specialized in the high precision processing. We mainly produce oil and gas valve parts, fluid hydraulic type high pressure quick connection parts, sensor parts, wind power equipment parts, auto parts, etc. We now have over 100 units of imported and domestic CNC equipments, various grinding machines (surface grinding, internal and external circular grinding, coreless grinding) and hardness tester, projector, profilometer, coordinate measuring machine and other testing equipments.

Since establishment, we have been adhering to the credibility principle, honest cooperation and strict management for the purpose of service. We also has been adhering to the quality policy of full participation, continuous improvement, quality advancement, punctual delivery and customer satisfaction. Our company provide customers with high quality products, considerate service, strict quality, fast delivery, perfect production equipments, first-class technology, so that Shijin has a place in the industry.

Main Production Equipment List:

No. | Name | Model | QTY | Equipment Manufacturer | System | Spec./ Range of Work | Accuracy |

1 | CNC Machining Center | CMV920 | 1 | Doosan (Korea) | FANUC | 1000*500*530 | 0.0025mm |

2 | CNC Machining Center | DNM500 | 1 | Doosan (Korea) | FANUC | 1000*500*530 | 0.0025mm |

3 | CNC Machining Center | CMV435 | 2 | Doosan (Korea) | FANUC | 1000*500*530 | 0.0025mm |

4 | CNC Machining Center | 850B | 2 | Jieyongda | FANUC | 1000*500*530 | 0.0025mm |

5 | CNC Machining Center | V435 | 2 | Doosan (Korea) | FANUC | 1000*500*530 | 0.0025mm |

6 | CNC Machining Center | DNM655 | 1 | Doosan (Korea) | FANUC | 1000*500*530 | 0.0025mm |

7 | CNC Machining Center | DNM415 | 2 | Doosan (Korea) | FANUC | 1000*500*530 | 0.0025mm |

8 | CNC Machining Center | VM1370L | 1 | Yonglida | FANUC | 726*430*510 | 0.01mm |

9 | Swiss-type Automatic Lathe | STAR-20 | 10 | STAR (Japan) | FANUC | ∮20*200(D*L) | 0.0025mm |

10 | Swiss-type Automatic Lathe | A20 | 2 | Citizen(Japan) | FANUC | ∮20*200(D*L) | 0.0025mm |

11 | CNC Lathe | Lynx225 | 4 | Doosan (Korea) | FANUC | ∮200*500(D*L) | 0.005mm |

12 | CNC Lathe | Lynx235 | 4 | Doosan (Korea) | FANUC | ∮200*500(D*L) | 0.005mm |

13 | CNC Lathe | GT-400 | 20 | Gongtie | SYNTEC-6TA | ∮200*500(D*L) | 0.005mm |

14 | CNC Lathe | 6136/6351A/3210S | 52 | Shanghai | GSK980TDb | ∮200*500(D*L) | 0.005mm |

Main Testing Equipment List:

No. | Name | Model | QTY | Equipment Manufacturer | Accuracy | ||

1 | CMM | Croma686 | 1 | Serein Measurement Technique | 0.001mm | ||

2 | Image Measuring Instrument | YVM3020C | 1 | Dongguan Yuanxing Optical Instrument | 0.001mm | ||

3 | Probe Image Measuring Instrument | YVM3030T | 1 | Dongguan Yuanxing Optical Instrument | 0.001mm | ||

4 | Contour Shape Measuring Machine | C1600G-13 | 1 | Tokyo Precision Equipment | (1+2L/100)um | ||

5 | Rockwell Hardness Tester | HR-150A | 1 | Laizhou Huayin | 1HRC | ||

6 | Roughness Tester | TR200 | 1 | Beijing Shidaizhifeng Instrument Co., Ltd | 0.001um | ||

7 | Roughness Tester | SJ-210 | 1 | Mitutoty | 0.001um | ||

8 | Concentricity Measuring Instrument | JS-A-10WC | 1 | Dongguan Tsugami Machine Electricity | 0.001mm | ||

9 | Digital Tesla Meter | HT20 | 1 | Shanghai Hengtong Magnetic Electricity | 0.1mT | ||

10 | Eddy Current Thickness Meter | ED300 | 1 | Shenyang Tianxing Test Instrument | 0.1um | ||

For more information, request a quote to get started on a project with us.